Modern internal combustion engines rely on a precise balance of mechanical efficiency and reliability. One small yet crucial component that makes this possible is the finger follower — a vital part of the valvetrain system responsible for transferring motion from the camshaft to the engine valves.

Finger followers may be small, but their role in ensuring optimal valve timing, reduced friction, and improved fuel efficiency is immense. This article explores what finger followers are, how they work, their advantages over older systems, and how to choose the right ones for your vehicle.

What Are Finger Followers?

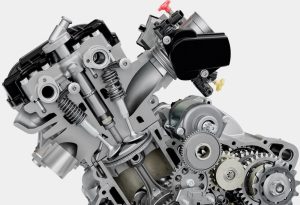

A finger follower is a type of valve actuation lever used in modern overhead cam (OHC) and double overhead cam (DOHC) engines. It acts as an intermediary between the camshaft lobe and the engine valve. When the camshaft rotates, the cam lobe pushes against the finger follower, which in turn opens the valve to allow air and fuel into the combustion chamber or to expel exhaust gases.

Unlike traditional rocker arms, finger followers are lighter, more compact, and designed for higher RPMs, making them a perfect fit for performance and efficiency-focused engines.

How Finger Followers Work

To understand how finger followers function, it helps to visualize their position within the valvetrain.

| Component | Function | Connection |

|---|---|---|

| Camshaft | Provides the lifting motion via rotating lobes | Contacts the top surface of the finger follower |

| Finger Follower | Transfers motion from the camshaft to the valve | Acts as a lever between camshaft and valve stem |

| Valve Stem | Opens or closes to control airflow | Receives force from the finger follower |

| Hydraulic Lash Adjuster (HLA) | Maintains zero clearance in the valvetrain | Supports the follower pivot point |

Here’s the simplified process step-by-step:

-

Camshaft rotation: As the camshaft spins, its lobe rises.

-

Follower movement: The cam lobe pushes on one end of the finger follower.

-

Valve actuation: The other end of the follower presses the valve stem downward, opening the valve.

-

Valve closure: As the cam lobe moves away, a valve spring pushes the valve back up, closing it.

-

Continuous adjustment: The hydraulic lash adjuster ensures proper clearance, reducing noise and wear.

This mechanism repeats thousands of times per minute, allowing precise valve timing and optimal engine breathing.

Types of Finger Followers

Different engine designs use various types of finger followers to match performance and durability requirements.

| Type | Description | Common Applications |

|---|---|---|

| Solid Finger Follower | A simple, rigid lever without hydraulic adjustment | High-performance or racing engines |

| Hydraulic Finger Follower | Includes a hydraulic lash adjuster to automatically maintain clearance | Most modern passenger cars |

| Roller Finger Follower (RFF) | Features a small roller on the cam-contact surface to minimize friction | Widely used in fuel-efficient engines |

Advantages of Finger Followers

Finger followers are an advancement over traditional rocker arm systems, offering several key benefits:

Reduced Friction

Roller-type followers significantly decrease metal-to-metal contact, reducing frictional losses and improving fuel economy.

Compact Design

Their smaller, lightweight design helps reduce overall engine mass and allows for higher RPMs.

Improved Efficiency

Better control of valve timing enhances combustion efficiency, leading to lower emissions and improved power delivery.

Quieter Operation

The combination of hydraulic adjusters and precision engineering leads to smoother, quieter valve operation.

Extended Component Life

Less wear and lower friction mean longer-lasting engine components and reduced maintenance needs.

Common Issues with Finger Followers

Although generally reliable, finger followers can experience wear or failure over time — especially in engines that operate at high RPM or lack regular maintenance.

Typical symptoms of worn or failing finger followers include:

-

Ticking or tapping noise from the engine

-

Loss of power or rough idling

-

Misfires or poor acceleration

-

Metal debris in engine oil

-

Irregular valve movement (visible with valve cover removed)

Causes may include:

-

Insufficient lubrication or dirty oil

-

Excessive heat or friction

-

Faulty hydraulic lash adjuster

-

Camshaft wear or misalignment

Regular oil changes using the manufacturer’s recommended grade can greatly extend the lifespan of finger followers and associated components.

Maintenance and Replacement Tips

To maintain optimal engine performance:

-

Inspect regularly: During major services, have your mechanic inspect the valvetrain for excessive wear.

-

Use quality oil: Clean, high-quality oil ensures proper lubrication.

-

Replace in sets: If one finger follower shows signs of damage, replace the entire set to maintain balance and timing.

-

Check the camshaft: Always inspect cam lobes for scoring or pitting when replacing followers.

-

Follow torque specifications: When installing new components, adhere strictly to manufacturer torque settings.

When replacement is necessary, make sure to choose parts that meet OEM standards. You can explore a wide range of quality options here:

Buy Finger Followers online

Comparison: Finger Followers vs. Rocker Arms

| Feature | Finger Follower | Rocker Arm |

|---|---|---|

| Size & Weight | Compact and lightweight | Larger and heavier |

| Efficiency | Lower friction, better fuel economy | Higher friction, more energy loss |

| RPM Capability | Excellent at high speeds | Limited by mass and inertia |

| Maintenance | Minimal with hydraulic systems | May require periodic adjustment |

| Noise Levels | Quieter due to precise design | Louder at high RPM |

Future Trends in Finger Follower Technology

As automotive engineering continues to evolve, finger follower design is improving too. Modern advancements include:

-

Variable Valve Timing (VVT) integration for adaptive performance

-

Low-friction coatings like DLC (Diamond-Like Carbon) for longer life

-

Lightweight alloys and composites to further reduce mass

-

Smart hydraulic systems that adjust dynamically to engine load

These innovations help manufacturers meet stricter emission standards while improving responsiveness and reliability.

Conclusion

Finger followers are a perfect example of how modern engine engineering combines simplicity and sophistication. By reducing friction, improving timing accuracy, and enhancing fuel efficiency, they play a key role in today’s high-performance and eco-friendly engines.

Whether you drive a compact sedan or a turbocharged sports car, maintaining your valvetrain in top shape is essential. If your engine shows signs of valvetrain wear or noise, consider replacing your finger followers with reliable, OEM-quality parts available here:

Buy Finger Followers online